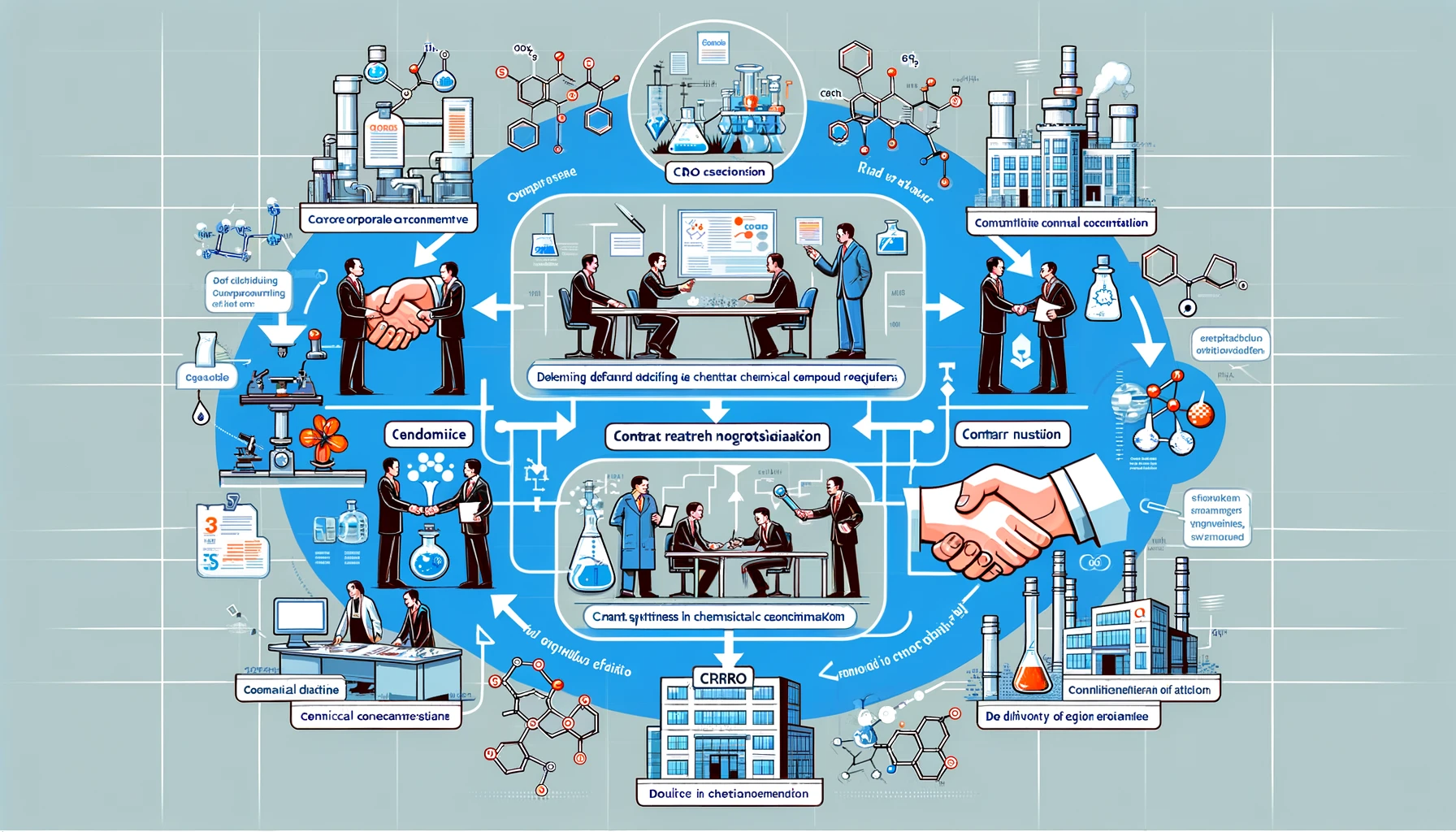

Process for Outsourcing Chemical Customization Projects

Companies identify a need for a unique chemical compound and define specific requirements. After searching for and evaluating suitable CROs based on expertise, capabilities, and compliance, they issue Request for Proposals outlining the project scope. CROs bid on projects, which companies assess to select the best fit. Contract negotiation and signing formally establish the collaboration under agreed terms. The CRO then executes the chemical synthesis project, with regular communication and quality checks. Finally, the CRO delivers the verified customized chemical, completing the outsourcing process. Key steps involve defining needs, evaluating CROs, negotiating contracts, executing synthesis, quality control and delivery of the bespoke chemical.